ERW165 tuubooyinka alxanka leh

Sharaxaada wax soo saarka

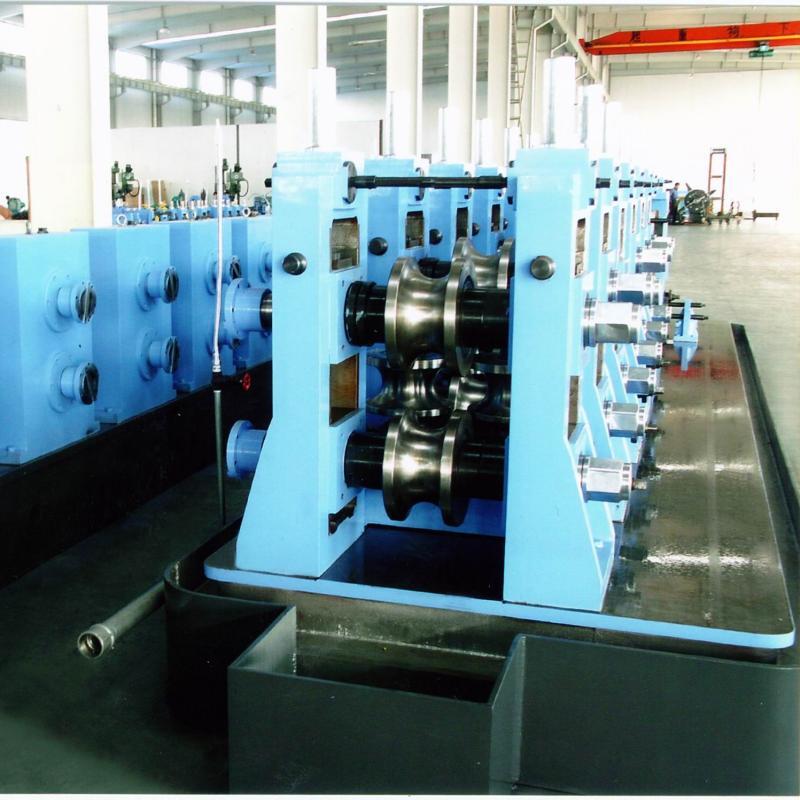

ERW165 tuubada mil/oipe mil/soosaarka tuubooyinka alxanka/mashiinka samaynta tuubooyinka waxaa loo isticmaalaa in lagu soo saaro biraha birta ah ee 76mm ~ 165mm OD iyo 2.0mm ~ 6.0mm ee dhumucda derbiga, iyo sidoo kale tuubo wareeg ah oo u dhiganta, tuubo laba jibbaaran iyo tuubo qaabaysan oo gaar ah.

Codsiga: Gl, Dhismaha, Gawaarida, Tubooyinka Makaanikada Guud, Alaabooyinka, Beeraha, Kiimikada, 0il, Gaaska, Wadnaha, Dhismaha

| Alaabta | ERW165mm Tube Mill |

| Qalabka lagu dabaqi karo | HR/CR, Gariiradda Xadhkaha Kaarboon-hooseeya,Q235,S2 35,Gi Strips. ab≤550Mpa, sida≤235MPa |

| Dhererka goynta tuubooyinka | 3.0 ~ 12.0m |

| Dulqaadka dhererka | ±1.0mm |

| Dusha sare | Iyada oo dahaarka Zinc ama aan lahayn |

| Xawaaraha | Xawaaraha ugu badan:≤100m/daqiiqo (waxaa lagu beddeli karaa iyadoo loo eegayo shuruudaha macmiilka) |

| Kuwo kale | Dhammaan tuubooyinka waa kuwo la alxanayo inta jeer ee badan Middi gudaha iyo dibaddaba welded bay ahayd laga saaray |

| Qalabka rullaluistemadka | Cr12 ama GN |

| Tuuji duub | H13 |

| Baaxadda qalabka tuubbada alxanka leh ent | Haydarooliga double-Mandrel un-coiler Xiritaanka Haydarooliga&Alxanka Toos ah ee Toosinta Accumulator Samaynta & Mashiinka Cabbirka Nidaamka Xakamaynta Korontada HFWelder State Adag (AC ama Darawalka DC) Kumbuyuutarka Duulaya miinshaar/Qalabka Goynta Orod miiska |

| Dhammaan qalabka iyo agabka kaalmeeya, sida uncoiler, motor, bearing, cut ting saw, roller, hf, iwm., Dhammaan waa magacyo sare. Tayada waa la dammaanad qaadi karaa. | |

Socodka Geedi socodka

Gariiradda birta ah → Qalab laba-gacanood ah → dhogorta iyo dhamaadka goynta & alxanka → Ururinta gariiradda → Samaynta (Cutub fidsan + Unug wada wadida + Unug samaysa → Kaydinta Bakhaarka

Faa'iidooyinka

1. Saxnaanta Sare

2. Wax soo saarka sare ee wax soo saarka, Xawaaraha khadka wuxuu noqon karaa ilaa 130m / min

3. Xoog Sare, Mashiinku wuxuu u shaqeeyaa si xawli ah, kaas oo hagaajinaya tayada alaabta.

4. Heerka wax soo saarka wanaagsan oo sarreeya, wuxuu gaaraa 99%

5. Khasaare hooseeya, Khasaaraha unugga oo hooseeya iyo qiimaha wax-soo-saarka oo hooseeya.

6. 100% beddelka qaybaha isku midka ah ee qalabka isku midka ah

Tilmaamid

| Walxaha ceeriin | Qalabka gariiradda | Birta Kaarboon-hooseeya,Q235,Q195 |

| Ballaca | 240mm-520mm | |

| Dhumucda: | 2.0mm-6.0mm | |

| Aqoonsiga gariiradda | φ580- φ700mm | |

| Gariiradda OD | ugu badnaan: φ1800mm | |

| Miisaanka gariiradda | 5.0-6.0Tons | |

| Awood wax-soo-saarka | Dhuumaha Wareegga | 76mm-165mm |

|

| Dhuumaha labajibbaaran & afargeesle | 60*60mm-130*130mm 40*80mm-100*160mm |

|

| Dhumucda darbiga | 2.0-6.0mm (tuubo wareeg ah) 2.0-5.0mm (tuubo laba jibaaran) |

|

| Xawaaraha | Ugu badnaan.50m/min |

|

| Dhererka Dhuumaha | 3m-12m |

| Xaaladda Aqoon-is-weydaarsiga | Awood firfircoon | 380V, 3-waji, 50Hz (waxay kuxirantahay xarumaha deegaanka) |

|

| Awoodda xakamaynta | 220V, hal-waji, 50 Hz |

| Baaxadda xariiqda oo dhan | 85mX7m (L*W) | |

Hordhaca Shirkadda

Ka imanaya caddaynta dhexdhexaadka ah, qaybo cajiin ah oo wareegsan ayaa go'ay ama si tartiib tartiib ah loo fidiyay iyada oo loo marayo taxane rodol ah oo loogu diyaargaroobayo qaabaynta ugu dambeysa. Xaashidu waxay inta badan ka kooban tahay 2-3 qaybood (oo taxane ah) oo madax rullaluley ah oo Teflon-dahaarka ah kuwaas oo u dhexeeya cajiinka cajiinka si tartiib tartiib ah loo simo.

Sheeting waxay khuseysaa xoogag walbahaarka (cadaadiska) kaas oo ka caawiya inuu soo saaro cutubka cajiinka si unugyada hawo ee waaweyn ee loo horumariyo inta lagu jiro wareejinta badeecada ama caddaynta dhexdhexaadka ah ayaa hoos loo dhigaa kuwa yaryar si loo gaaro hadhuudh fiican ee alaabta la dhammeeyey.

Qalabka rogaha waxaa loo habeeyey si ay farqiga/nadiifinta u yaraato si tartiib tartiib ah marka cajiinka uu dhex marayo. Tani waa muhiim si kor loogu qaado hoos u dhigista dhumucda cajiinka. Suuragal ma noqon doonto in hal tallaabo oo qura lagu simo qaybaha cajiinka iyada oo aan waxyeello aan laga soo kaban u geysan dhismaha unugga gaaska iyo gluten.

Ka dib marka la dhex maro rollers-yada sare, gabal cajiinku wuxuu noqonayaa mid aad u dhuuban, weyn, oo qaabaysan. Cajiinka fidsan ee ka soo baxaya rullaayasha hoose ayaa diyaar u ah inay ka hoos maraan silsiladda qallooca.